Quality

Our #1 priority at QA1 is quality, which is why our quality system is certified to the ISO 9001:2015 standard. QA1’s products are designed, built, and tested to ensure consistent quality, ultimate reliability, and unbeatable performance. We follow strict processes, use precision machinery, and inspect all of our products to ensure the quality meets our high standards.

WHAT DOES BEING CERTIFIED TO THE ISO 9001:2015 STANDARD MEAN?

ISO 9001:2015 sets out the criteria for a quality management system and is the only quality standard of the ISO 9000 family that you can receive certification for. Based on a number of principles, including a strong customer focus, the motivation of top management, the process approach and continual improvement, this certification helps ensure that customers get consistent, high-quality products and services. QA1 performs internal audits and annual outside vendor audits to check how our quality management system is working.

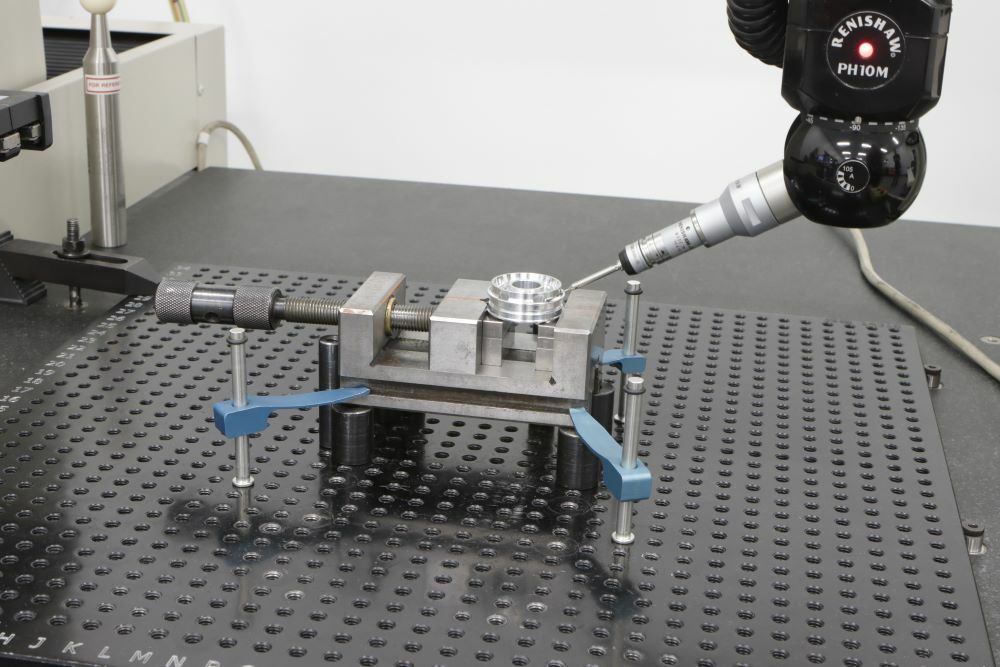

INSPECTION MACHINES AND TOOLS

Our quality department uses several machines and tools to check the quality of our products throughout the manufacturing process, including but not limited to:

• Dyno Testers

• Spring Rate Tester

• Go and No-Go Gages

• Pin Gages

• Calipers

• Rockwell Hardness Tester

• Tinius Tensile Strength Tester

• Micrometers

• Optical Comparator

• Bore Gages

• Digital Drop Indicator

• Vernier Height Gage

• Surface Plate and Angle Plate

• Coordinate Measuring Machine

100% DYNO TESTED AND SERIALIZED SHOCKS AND STRUTS

At QA1, we are focused on crafting the most reliable, consistent, and highest-performing shocks and struts. To achieve this, every rebuildable shock absorber and strut is dyno tested and serialized so you can rest assured they’re built to exact specifications. The fact that our warranty rate is almost non-existent is a testament to the care we take with each and every product we make.

CARBON FIBER DRIVESHAFT TESTING

QA1’s carbon fiber driveshaft testing meets or exceeds SFI specification 43.1. Our Advanced Materials Division uses many techniques to evaluate and ensure the quality of our products. Not only are the finished carbon fiber driveshafts tested, but the materials used to make them are tested throughout the process as well. Some of the in-house material tests include tension, compression, shear, three point bend and surface roughness. We also perform imaging techniques with a high magnification microscope to analyze the composites for fiber volume, layer analysis and to avoid potential void content. Harmonic testing is done to determine the natural frequency of the driveshaft and a modal analysis is performed to ensure the composite driveshaft meets the applications’ requirements for NVH (noise, vibration, and harshness).

TEST FIT AND TRACK TESTED

Many of QA1’s employees are racers or automotive enthusiasts themselves and understand the needs and goals of our customers from firsthand experience. We know that dyno testing, computer evaluations and endurance tests are only valuable if they can also result in real world performance. QA1 often works with well-known industry icons to get feedback during the prototype and testing phase. We make sure every product is test fit, track tested and driver or racer approved before it begins production.

QA1 QUALITY POLICY

Quality and Affordability are the #1 priority at QA1. We achieve this by having a robust Quality Management System and a culture of continuous improvement.