This 1956 Chevy 3100 Is The Ultimate DIY Pro-Street Project

Rob McPherson’s Pro Street-style 1956 Chevrolet 3100 pickup has been more than a simple project—it has been the engineer-by-trade’s opportunity to get his hands dirty and make a statement utilizing DIY ingenuity. From its beginnings as an abandoned project in a Wisconsin garage, this truck has been transformed into a big-tire cruiser, designed for driving the back roads but equally at home on the drag strip. McPherson, today the Vice President of Business Development at QA1, combined his professional knowledge with years of experience to build a truck that reflects both his passion for cool cars and his technical versatility.

A DIY Vision

Rob began this build in 2013, when he came across the 1956 Chevy Task Force in a rough, incomplete state. While most would have seen a pile of rust and abandoned dreams, Rob saw potential. With a big-block Chevy engine as his starting point, he set off on a journey that would push his limits and expand his skills. “I actually started with an engine and said I was going to build everything else around that,” he says.

After completing a factory-original restoration of a 1965 Corvette that’s in his collection, McPherson craved a project that would allow him complete freedom—no rules, no constraints, just raw creativity. The 1956 Chevy 3100 provided the perfect canvas for his vision: a 10-second street-legal hot rod that could double as a comfortable cruiser.

Crafty Fabrication

To lay a solid foundation for his project, Rob made the strategic decision to modify the factory frame, starting with grafting in a subframe from a 1969 Camaro. The original solid front axle, while durable, didn't offer the performance advantages of a modern independent front suspension (IFS). It limited handling and responsiveness, making it less ideal for the kind of driving Rob envisioned. By eliminating the solid axle and replacing it with a more advanced setup, Rob set the stage for significant performance upgrades. This crucial first step opened the door for modern suspension components and enhanced drivability, giving him a platform to build a vehicle capable of tackling both street and track environments with ease.

To lay a solid foundation for his project, Rob made the strategic decision to modify the factory frame, starting with grafting in a subframe from a 1969 Camaro. The original solid front axle, while durable, didn't offer the performance advantages of a modern independent front suspension (IFS). It limited handling and responsiveness, making it less ideal for the kind of driving Rob envisioned. By eliminating the solid axle and replacing it with a more advanced setup, Rob set the stage for significant performance upgrades. This crucial first step opened the door for modern suspension components and enhanced drivability, giving him a platform to build a vehicle capable of tackling both street and track environments with ease.

QA1 components played a significant role in perfecting the truck’s suspension and handling. The front suspension setup features QA1’s full coilover kit for the first-gen Camaro, with 500-pound QA1 coilover springs and Proma Star double adjustable shocks. These QA1 shocks, designed for a balance of ride quality and adjustability, allow McPherson to fine-tune the truck’s stance and performance characteristics. Whether he’s on the street or the drag strip, this suspension setup provides the control needed to handle the truck’s horsepower.

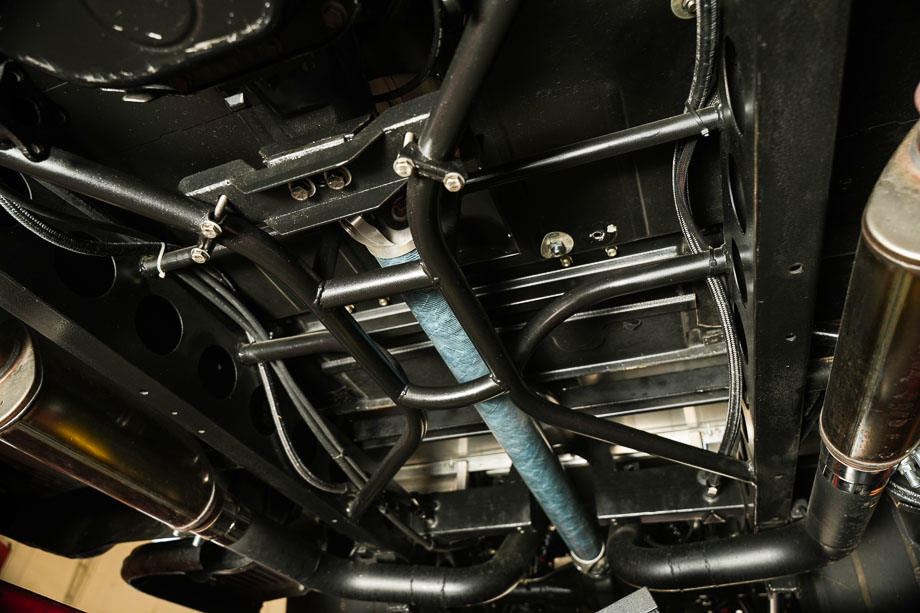

Out back, McPherson fabricated a 2x3 tubular back half and installed a custom 4-link setup with a Watts link for lateral stability, again utilizing QA1’s performance suspension components. The rear suspension features QA1’s MOD Series four-way-adjustable coilovers, providing the ultimate in adjustability to fine-tune ride quality and handling in any driving scenario. The combination of these components provides the kind of ride control that DIY builders hope to achieve, thanks in part to McPherson’s engineering background and hands-on experience.

McPherson’s dedication to building his project the right way is evident in every aspect of the truck’s fabrication. He not only boxed the factory frame for added stiffness but also fabricated a custom cross brace with an integrated transmission mount and driveshaft loop. This added rigidity helps to maintain the truck’s structural integrity under hard acceleration, ensuring the power is put to the ground effectively. In addition to the Camaro front control arms and shocks, Rob utilized QA1 rod ends, tube end adapters, and high misalign spacers.

SHOP DIY SUSPENSION COMPONENTS

The Heart of the Beast: A 496 Big Block Chevy

Under the hood lies a 496-cubic inch big-block Chevy engine built by McPherson himself. This engine is pure old-school hot rodding, featuring a stroker crank, aluminum AFR heads, and a throaty 950 cfm FST carburetor sitting atop an Edelbrock Victor Jr. intake manifold. The engine’s specs are impressive, producing 650 horsepower and 675 lb-ft of torque on the dyno—plenty of grunt to push this truck to 10-second quarter-mile times.

McPherson’s attention to detail extends to every part of the engine build. From the Scat forged crankshaft and connecting rods to the Comp Cams custom roller camshaft, every component was chosen for power and durability. The engine breathes through custom 2-inch primary headers, which McPherson fabricated himself after cutting and re-routing fender well headers originally designed for a 1957 Chevy. These headers are paired with a custom 3-inch exhaust system and Cherry Bomb Salute mufflers, giving the truck an unmistakable roar when it fires up.

Transmission and Drivetrain: Built to Handle the Power

Power is nothing without control, and McPherson spared no expense in ensuring the drivetrain could reliably handle the power output of the big 496. The transmission is a full manual 4L80 from Extreme Automatic, complete with a transbrake and lock-up converter. A TCI Diablo shifter and a custom 9.5-inch torque converter make sure that power is transferred smoothly to the Dana 60 rear axle, which McPherson sourced from an old Ford truck and rebuilt with 35-spline axles and a 4.10 gear ratio.

Power is nothing without control, and McPherson spared no expense in ensuring the drivetrain could reliably handle the power output of the big 496. The transmission is a full manual 4L80 from Extreme Automatic, complete with a transbrake and lock-up converter. A TCI Diablo shifter and a custom 9.5-inch torque converter make sure that power is transferred smoothly to the Dana 60 rear axle, which McPherson sourced from an old Ford truck and rebuilt with 35-spline axles and a 4.10 gear ratio.

Another key component in the truck’s performance is the QA1 carbon fiber driveshaft, which is both lightweight and engineered for strength, this driveshaft reduces rotating mass, allowing for quicker acceleration—an essential factor in hitting 10-second quarter-mile times. The driveshaft’s durability ensures it can withstand the rigors of high-horsepower applications, making it a perfect match for the 650-horsepower big block Chevy engine powering the truck.

Interior and Custom Fabrication: A Personal Touch

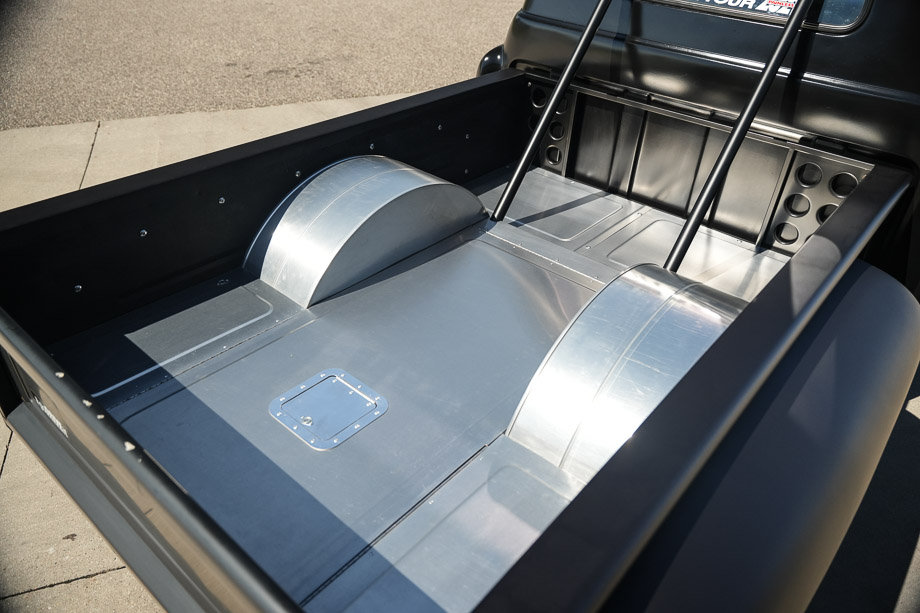

One of the most unique aspects of McPherson’s build is the level of custom fabrication he undertook in his home garage. From the aluminum bead-rolled bed floor with storage access doors to the 8.50-certified chromoly roll cage, McPherson’s fingerprints are all over this truck. He even fabricated the bomber-style seats, which offer maximum legroom in the relatively tight ’56 cab, and a distinct hot rod aesthetic.

Inside the cab, the truck maintains a no-frills approach with bare aluminum door panels, a smoothed dash, and Stewart Warner Deluxe gauges. The minimalist interior design complements the truck’s performance-oriented nature while still offering enough comfort for long drives.

A True Driver’s Truck

Despite its raw performance, McPherson’s 1956 Chevy is no trailer queen. He built the truck to be driven—fast. Since completing the build in 2020, McPherson has taken it on the Hot Rod Power Tour, local car shows, and QA1’s #goDRIVEit cruises. Whether it’s on the drag strip or the highway, this truck turns heads.

McPherson’s planning and execution resulted in a truck that not only looks the part but also performs like you’d expect of a build of this caliber. The combination of DIY fabrication, high-performance components, and a clear vision of what he wanted to achieve has paid off. His advice to others embarking on similar builds? “Know what you want to end up with to avoid rework. Be realistic about what you can do yourself and what you need to hire out.”

Wrapping Up

Rob's Chevy 3100 is the epitome of a well-executed DIY build, with the perfect blend of old-school hot rodding and modern suspension technology, this truck is both track-ready and street-legal cruiser. McPherson’s dedication to using his own hands and tools combined with his use of QA1 components has resulted in a truck that stands out in any crowd.