Are Tubular Control Arms The Best Classic Vehicle Upgrade?

When discussing classic car restoration or performance upgrades, the focus often gravitates towards components such as engine modifications and aesthetics like paint jobs, wheels, and interior restorations. However, one critical area that often goes underappreciated, yet is fundamental to both performance and driving comfort, is the suspension system— specifically, the control arms. OEM stamped steel control arms are commonly thought go as adequate, but the benefits of modern, tubular control arms are numerous and can greatly improve your driving experience perhaps more than any other suspension upgrade.

Construction and Materials: Lighter, Stronger, Better

The fundamental difference between QA1 tubular control arms and OEM stamped steel control arms starts with the materials and construction methods used. OEM control arms are typically made from stamped steel, a process that involves shaping metal sheets through a die to form the control arm. While this method is cost-effective and durable, it results in components that are heavy, and that extra heft means the suspension cannot act as quickly as it would if it were lighter.

In contrast, QA1’s USA-made tubular control arms are engineered with performance in mind. These components are constructed from high-strength, low alloy lightweight steel tubing. The material and the tubular design significantly reduces the weight of the control arms compared to their stamped steel counterparts, contributing to lower unsprung mass. Unsprung mass refers to the weight of the suspension components not supported by the springs, including wheels, tires, spindles, brakes, and half the weight of the control arms. Reducing unsprung mass is critical because it allows the suspension to react more quickly to road imperfections, improving both handling and ride quality.

Optimized Geometry: Bringing Classic Cars into the Modern Era

One of the most significant advantages of QA1 tubular control arms over OEM control arms is the optimized geometry designed to meet modern performance standards. OEM control arms, especially those in classic cars, were designed decades ago when performance expectations were vastly different. Cars in that era also rode on bias-ply tires, which had an altogether different traction curve than today’s modern radial tires.

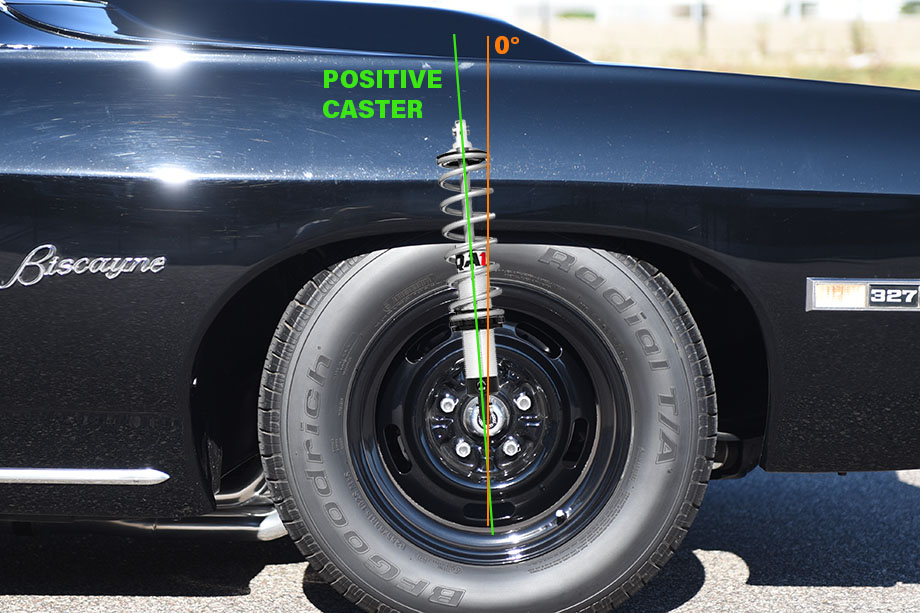

The classic cars of the 1960s and ‘70s commonly had at most 2-3 degrees of positive caster, which left them feeling very “vague” in terms of handling and road feel at the driver’s fingertips. In the decades since, automotive manufacturers have adopted new philosophies and modernized vehicles with more caster, giving them a far more connected driving feel than their ancestors.

QA1’s tubular control arms are designed with modern suspension geometry in mind, offering greater adjustability and the ability to achieve alignment settings that were not possible with OEM components. One critical aspect of this improved geometry is the adjustment of camber and caster angles, both of which play a pivotal role in handling performance. QA1 control arms feature 5-7 degrees of positive caster, depending on the vehicle make and model.

Enthusiasts commonly perform rack and pinion steering conversions to their classic vehicles instead of upgrading their control arms, in an attempt to improve the twitchy driving feel, when in reality, it is the greater caster angles made possible by the control arms that will best correct this. This modern geometry, facilitated by the control arms, is what makes your classic vehicle drive like it was built within the last decade, rather than half a century or more ago.

Understanding Caster: Why Positive Caster is Essential

Caster angle is the forward or rearward tilt of the steering axis when viewed from the side of the vehicle. It’s a critical alignment angle that affects how the car handles, particularly at higher speeds. Classic cars were designed with minimal caster, because the performance demands of the era were different. These cars were engineered to provide a comfortable ride and manageable steering effort with bias-ply tires.

However, in the modern context, more positive caster is highly desirable. Positive caster refers to the steering axis tilting toward the rear of the vehicle. The benefits of increased positive caster are numerous:

1. Improved Straight-Line Stability: Greater positive caster increases the self-centering effect of the steering, making the car more stable at higher speeds. This is particularly important for classic cars, which may otherwise feel “twitchy” or overly sensitive to steering inputs.

2. Enhanced Cornering Performance: Positive caster also increases the camber gain on the outside wheel during cornering. This means that as the vehicle turns, the outside wheel gains negative camber, maintaining the tire’s contact patch with the road and thereby enhancing grip. This results in better handling and more confident cornering, and better ability to center as the vehicle exits a corner.

3. Better Steering Feel: Increased caster enhances the steering feel, providing better feedback to the driver. This feedback allows the driver to feel the road surface and the car’s behavior more clearly, contributing to a more engaging and enjoyable driving experience.

With more positive caster compared to stock control arms, modern control arms are a critical upgrade for anyone looking to improve the handling and stability of their classic car.

Enhanced Camber Adjustability: Maximizing Tire Contact

In addition to caster, camber is another critical alignment angle that can be optimized with some of QA1’s tubular control arms. Camber refers to the tilt of the wheels when viewed from the front of the vehicle—negative camber means the tops of the wheels tilt inward, while positive camber means they tilt outward. Proper camber settings are essential for maximizing tire contact with the road, particularly during cornering.

QA1’s Pro-Touring tubular control arms feature an extended ball joint stud, which offers more negative camber gain, allowing for more precise alignment settings. This adjustability is especially important for performance-oriented drivers who want to dial in specific camber settings for track days or spirited driving.

Negative camber, when properly adjusted, improves grip during cornering by keeping more of the tire’s contact patch on the road as the suspension compresses. This is crucial for maintaining control and stability during high-speed turns. With QA1 tubular control arms, enthusiasts can achieve the ideal camber settings that suit their driving style and the specific demands of their vehicle.

QA1 Control Arms: Professional Presentation, The Ultimate In Fit & Finish

QA1 control arms feature forged ball joint housings that are integrated into the arm, with replaceable components that make them easy to work on and service. The integrated design reduces weight versus control arms that have provisions for OEM-style ball joints. Importantly, as well, some vehicles with drop spindles will have limitations on wheel size because the typical ball joint and ball joint housing are situated close to the rim. QA1’s more compact, integrated design greatly increases compatibility with varying rim widths.

Additionally, QA1 utilizes advanced engineering and manufacturing processes to craft its control arms with a refined, OEM-like finish. The lower coilover mounts are stamped and laser-cut and robotically welded into the lower control arms, in a complex process that results in a product you can marvel at as soon as you take it out of the box.

The Overlooked Impact of Suspension Upgrades: More Than Just Performance

While the technical advantages of QA1 tubular control arms—such as reduced weight and optimized geometry—clearly benefit performance, it’s important to consider the broader impact of these upgrades on the overall driving experience. For many classic car owners, the joy of driving a vintage vehicle is not necessarily about pushing it to its limits on a racetrack, but about the sheer pleasure of the driving experience itself.

If you’re still running decades-old OEM control arms and have not replaced the bushings, that alone will make the benefits of aftermarket control arms obvious. And nobody truly loves replacing bushings—you have to use a torch or another source of heat, melt the rubber, and try to remove the sleeve in a rather messy, unpleasant process. With new control arms, you gain brand new bushings and ball joints and a much-improved driving experience out of the box. However, QA1 has engineered its control arms with high-grade bushings, which are ideal for weekend cruising and performance driving alike. Street control arms feature polyurethane bushings, while the pro-touring and drag racing arms sport ultra-low-friction and ultra-low-deflection composite bushings. These materials are more durable, and easier to replace and service. Polyurethane and composite bushings exhibit only a small fraction of the deflection that rubber bushings will commonly display—this can be as much as 3/8 of an inch. The pivot points of your control arms set your geometry, and these large amounts of deflection in your bushings negatively impact your tires contact patch when you're in a corner.

Classic cars, with all their charm and character, can often feel disconnected from the road compared to modern vehicles. Much of this can be attributed to the outdated suspension designs that don’t meet the standards of today’s driving expectations. QA1 tubular control arms bring these classic vehicles into the modern era by significantly improving the way they handle and respond to driver inputs.

It’s commonly believed that only high-performance driving scenarios, such as autocross or road course racing, would display the true benefits of aftermarket control arms, however, it’s in the every-day driving situations where the improvements are most evident.

Even for those who primarily use their classic cars for casual driving, the practicality of upgraded control arms should not be underestimated. The improved ride quality and handling make the car more enjoyable to drive, reducing fatigue on longer trips and making the vehicle easier to control in various driving conditions. For owners who compare their classic cars to modern daily drivers, QA1 tubular control arms bridge the gap, making the old feel new again.

This includes better straight-line stability, more predictable handling during cornering, and an overall smoother ride. The improved handling characteristics allow drivers to push their vehicles harder with more assurance, knowing that the suspension is equipped to handle the demands placed upon it. Whether navigating winding back roads or simply cruising through town, the difference is undeniable.

QA1 Tubular Control Arms—A Transformative Upgrade

Beyond just an upgrade, tubular control arms are an investment in your driving experience. By offering optimized geometry, reduced unsprung weight, and superior design and quality, these control arms address the limitations of antiquated OEM control arms, bringing classic cars into the modern age of performance and comfort.

Whether you’re a performance enthusiast looking to maximize your vehicle’s potential, or someone who just wants their classic car to handle and feel better on the road, QA1's USA-made tubular control arms offer clear advantages. They not only improve the vehicle’s performance but also enhance the overall driving experience, making your classic car not just a nostalgic artifact, but a machine that you can truly enjoy driving every day.