Autonomous Innovation

QA1's Cutting-Edge Suspension System Boosts Autonomous ATV’s Capabilities

KEY TAKEAWAYS:

- QA1 designed a customized coil-over shock solution for an autonomous ATV that required a cost-effective, durable, and compact design.

- The initial development process was streamlined by modifying an existing shock design to meet customer requirements.

- Collaborative efforts expanded the project scope to encompass the suspension sub-assembly, consolidating vendors and improving the client's in-house manufacturing efficiency.

CHALLENGE:

A client approached QA1 seeking a coil-over shock solution for an autonomous ATV that required a cost-effective compact design that delivered durability for rough terrains.

The challenge was to design a custom solution that met these unique demands, including custom shock valving for rough terrains, all within the confines of the compact platform.

SOLUTION:

Building upon an existing QA1 shock streamlined the development process by leveraging a proven design and manufacturing framework. The solution was tailored to the client's exacting specifications with modifications to the overall stroke, length, and valving. A custom coil-over spring was also designed to fit within the limited space.

After completing the physical shock and spring, the QA1 Engineering team collaborated with the client to further refine the overall design, testing various combinations of valving and spring rates to perfect it.

Throughout this process of focusing on the shock/spring configuration, the QA1 team also identified multiple opportunities to enhance the overall suspension assembly.

SUSPENSION ASSEMBLY:

This broader, solutions-focused collaboration between QA1 and our client led to the development of a complete sub-assembly, including the coil-over shock, upper and lower control arms, and a custom mounting plate.

Throughout the process, QA1’s design and engineering controls ensured that this sub-assembly solution met the client’s stringent requirements for cost and quality.

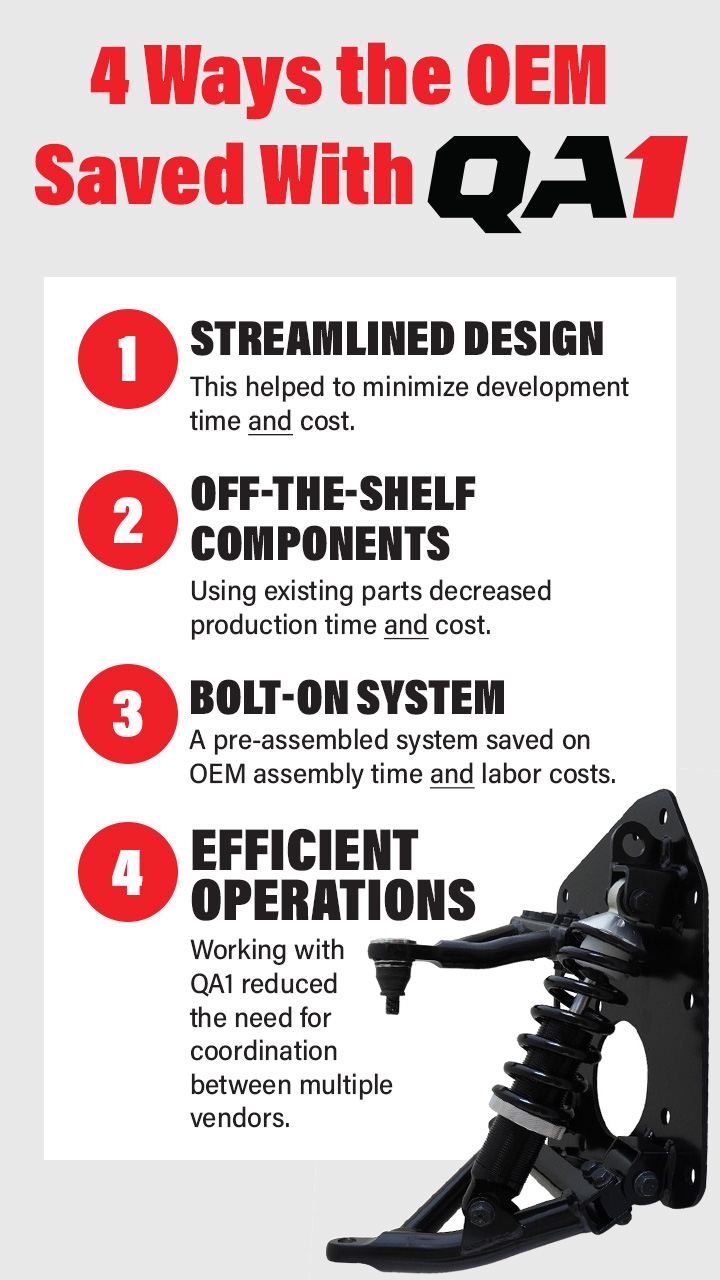

In the end, this sub-assembly solution benefited the client in several ways – by simplifying final assembly, improving efficiency, and offering substantial cost savings.

RESULT:

After internal and external testing, QA1 provided the OEM with a complete suspension sub-assembly. Even better, the design modifications allowed the client to leverage this assembly in several similar vehicles, addressing additional requirements.

The successful collaboration between QA1 and our OEM client not only met the initial challenge but also generated opportunities for future designs and applications.

HOW CAN WE HELP YOU?

QA1 is committed to assisting equipment manufacturers with innovative products and continuous improvement initiatives.

Whether designing an entire suspension system or seeking a component solution within an existing configuration, our team is ready to collaborate in whatever capacity best meets your requirements.

Please complete the form linked below to explore how QA1 can help you find, develop, or produce the right suspension and control solution for your needs and budget.

Sign up for the QA1 Quarterly Newsletter to receive quarterly updates, resources, and insights from QA1.