WHEN TO CONSIDER SELF-LUBRICATING, GREASABLE OR METAL TO METAL ENDS

THE BASICS

Selecting rod ends for any application requires consideration in a few areas. While load ratings often get most of the attention when selecting rod ends. Rod end design and their lubrication properties should be factored in to ensure the best product selection for optimal performance in your application.

In this article we will be looking at the variety of lubricated and non-lubricated rod ends and when each would be ideal in various scenarios. Understanding these fundamentals will aid in longer service life, lower maintenance costs, and greater customer satisfaction with your system.

METAL TO METAL

The first-rod end is QA1’s metal-to-metal rod end. As the name suggests, these rod end’s metal ball rides directly on the rod end’s metal race surface. This sort of rod end has no built-in lubrication properties and performs very well in a multitude of applications.

Metal to metal rod ends typical applications are in fixed-position installation applications (not all rod ends are used in motion control systems in which lubrication is necessary). This high component strength rod end’s primary benefit is having no lubrication breakdown concerns for extreme/high heat applications.

An important consideration in choosing this rod end style form factor is having no liner or grease to insulate noise. For applications where noise, vibration, and harshness may be a concern, a rod end with a PTFE liner between the ball and race would be a better product selection.

Self-Lubricating Rod Ends

Lubrication is very important in true motion control systems where rod end articulation is present. Proper rod end lubrication functions to prevents binding, squeaking, and other preventable undesirable side effects from the system.

Self-lubricated rod ends, or PTFE lined rod ends, are a great option for thousands of applications. One of the key benefits of this product type is its very low maintenance requirement. This is very important when physical access to the rod end itself for continual greasing proves to be difficult, or your customer simply needs the convenience of less frequent system maintenance.

Another area where a self-lubricated rod performs best is when there is a slight vibration or noise is an issue. The PTFE liner insulates the ball from the race, significantly dampening the noise. This benefit is applicable to both motion control systems or fixed installation applications.

Temperature is something you want to be considerate of with self-lubricated rod ends. The PTFE liner works best in temperatures between -65 to 325 degrees Fahrenheit. Luckily, most applications are well within that range, but if yours exceeds that, you may need to look at greaseable rod ends with high temp grease.

Greaseable Rod Ends

Greaseable rod ends are among the most popular rod ends in the field today. Unlike a PTFE liner that can wear over time, a greaseable rod end can continually be serviced, extending the product’s lifespan several times over.

A major consideration before selecting a greaseable rod end is the likelihood it will be greased at the appropriate intervals. A greaseable rod end is only a good option if it is truly serviced on a regular basis.

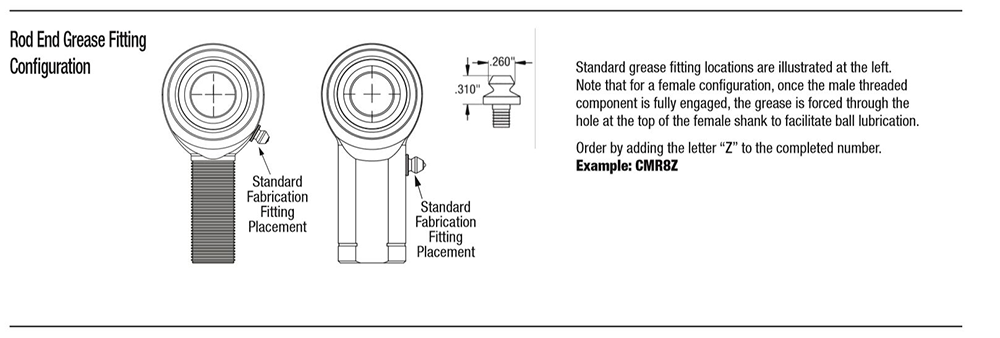

Of these three-rod end styles, greaseable rod ends have the lowest load rating. Drilling a hole into the body of the rod end for the grease fitting removes a portion of the rod end material that helps make up the overall strength. In general, this is not a concern, but make sure you understand your load requirements first. We invite you to call one of our technicians with any questions in calculating rod end loading.

In Summary:

QA1 rod ends are available in three basic styles and are available for your project regardless of your application’s lubrication and noise, vibration, and harshness requirements. Each style performs best in particular applications. Whether you need metal to metal, self-lubricating, or greaseable rod end, QA1 will have a solution for you.