WHY YOUR VEHICLE NEEDS A SWAY BAR

Whether you’re carving your way around a high-speed corner against the clock, performing hard launches on a sticky dragstrip, or simply enjoying some spirited backroad driving, body roll — the center of mass of your vehicle transferring unevenly to one side — upsets the balance of your vehicle, limits its performance capability via loss of grip, and becomes unpredictable. A stiff chassis inspires confidence and delivers improved performance in ways that your vehicle’s factory suspension system likely falls short.

WHY DO YOU NEED A SWAY BAR?

Off the showroom floor, suspension systems are typically engineered to prioritize road-going comfort and mass market appeal, not high performance driving and adjustability and certainly not increased power output, all of which place added demands on your chassis as you push its boundaries on the road or the track. Decades ago, sway bars were often options and instead of standard equipment, particularly on pickup trucks and other rigs built for utility and not high-speed corners. Instead, sway bars were more common on vehicles that prioritized handling and stability, like sports cars and pony cars.

THE BENEFITS OF AN AFTERMARKET TUBULAR SWAY BAR

Lightweight tubular sway bars are one of the best upgrades that you can give your vehicle to improve its handling characteristics, especially if your vehicle didn’t originally come equipped with them. Often recommended as one of the first and most impactful upgrades you can make, sway bars are effective and simple to install, and can make a world of difference in the balance and control of your vehicle. A sway bar works in conjunction with your vehicle’s shocks, springs, and other components and is designed to give your chassis the stiffness and stability it needs to keep your tires planted on the road, improving its performance and ride quality.

When cornering at high speed, the compliance that’s built into your vehicle’s suspension allows the suspended weight of the body to shift, or lean, in the direction of travel as the centrifugal force of the turn acts upon it, placing greater load on the suspension on one side of the vehicle. This process in turn upsets the balance of the vehicle, placing excess force on the suspension on one side, while unloading the suspension and reducing traction on the opposite side, setting your vehicle up for an unpredictable return to a “set” position as you exit the turn or segue into a breaking area.

In a drag racing application, the rotational forces of the driveline naturally want to twist the vehicle’s body to the right side, again placing excess force on that side of the vehicle and reducing the all-important transfer of weight on the left to keep the tire planted to the ground. As you increase horsepower output, this unwanted action only magnifies.

Sway bars are designed to counteract these forces by acting as a torsional spring to limit the ability of only one side of the suspension to compress. As your vehicle leans into a corner, it applies the sprung weight to the shocks and springs and ultimately to the tires on that side, causing the sway bar to twist. A well-tuned, tubular sway bar distributes the load of the vehicle’s weight transfer more evenly across all four tire contact patches — this leverage results in better grip and a more confident and consistent response from your vehicle.

HOW TO SELECT A SWAY BAR FOR YOUR VEHICLE

When choosing a sway bar for your vehicle, it's crucial to consider both the performance benefits and the ease of installation. QA1 engineers have designed its sway bars to optimize handling, drivability, and straightforward installation, leveraging factory mounting locations whenever possible.

QA1 sway bars are specifically designed for each vehicle application, considering material, diameter, and optimal mounting solutions.

Here’s why QA1 sway bars stand out:

Material and Construction:

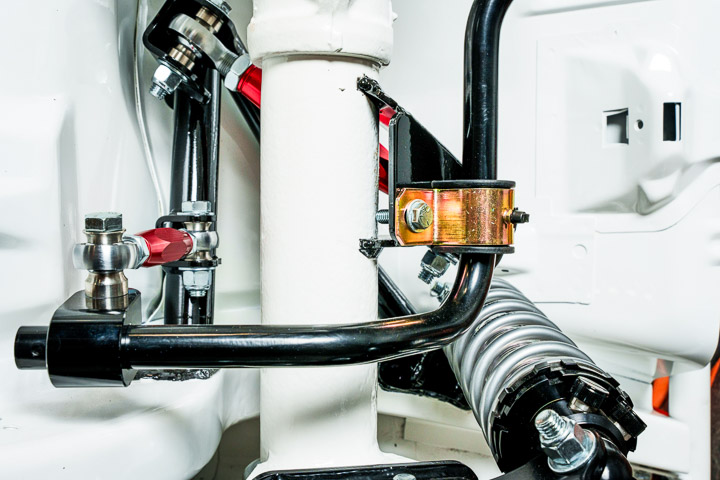

- Front Sway Bars: While bar diameter varies by application, many sway bars come from hollow 4130 chromoly steel with a 3/16” wall thickness, offering a lightweight yet stiff solution.

- All QA1 sway bars come with new mounting components, including bushings and end links, to replace worn-out parts and ensure a secure installation.

- Rear Sway Bars: Available in either hollow 4130 chromoly steel or heavy-duty solid 1045 cold-formed steel for robust performance.

Installation Components:

- Design and Functionality: QA1 sway bars utilize factory mounting locations to streamline installation, reducing the need for additional drilling.

- Optimized for large tires and ground clearance, they feature CNC-machined and welded bar ends, mandrel-bent tubing, and a durable powder-coat finish for a premium look.

By choosing QA1 sway bars, you get a product engineered for high performance and ease of installation, ensuring superior handling and drivability with a sleek, custom appearance.