BALL JOINTS 101: FREQUENTLY ASKED QUESTIONS

Ball joints may not be the first suspension components that spring to mind. However, they play a very pivotal role in the performance, comfort and safety of your vehicle’s suspension. Let’s take a closer look at how these critical parts function and answer some common questions.

WHAT IS A BALL JOINT?

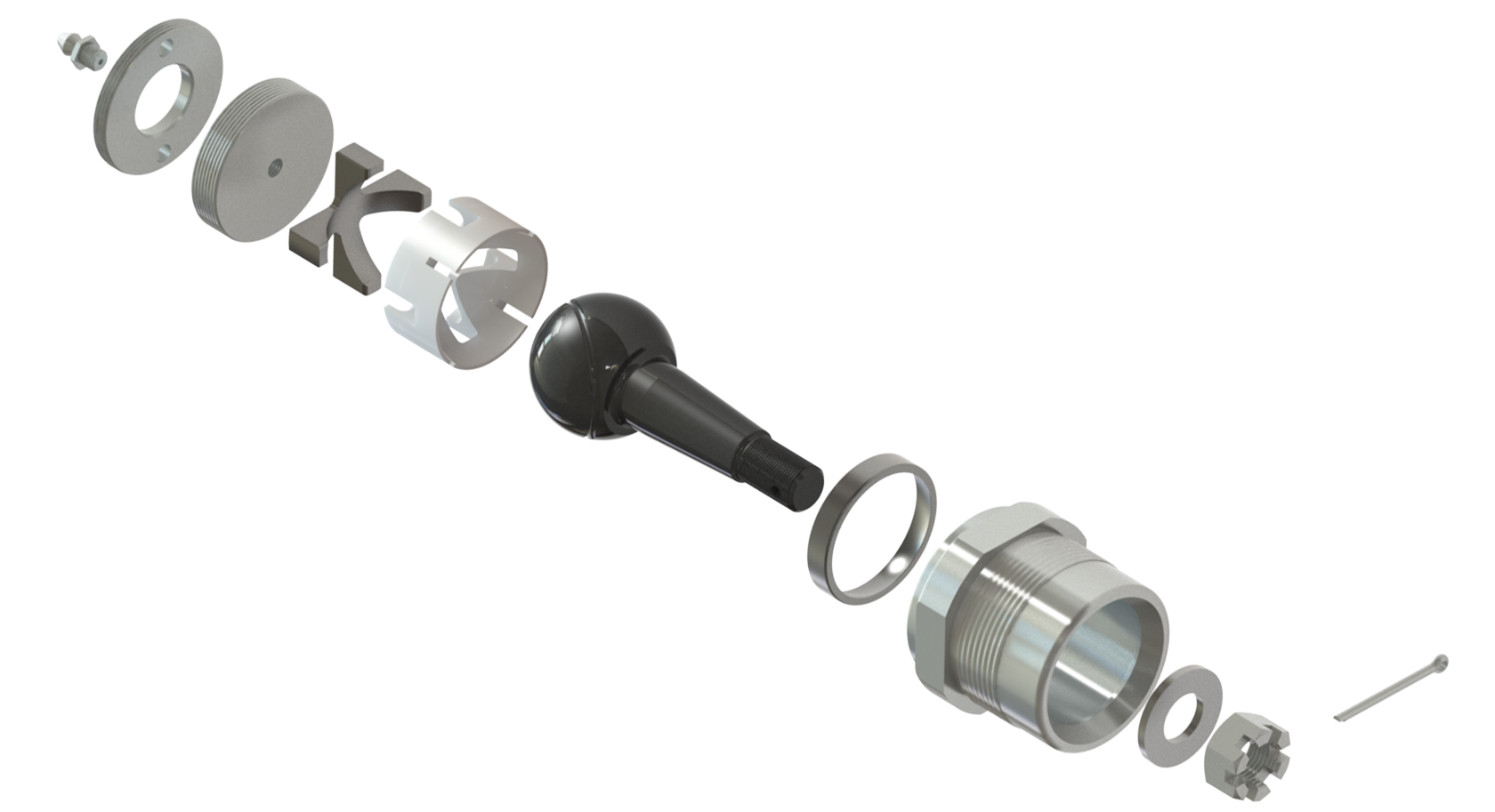

A ball joint is a type of linkage. It’s commonly used in both stock and aftermarket suspension components. Their unique design uses a ball and socket on one end and a tapered pin on the other. This allows one end to rotate within its cup. Certain suspension components can pivot and rotate when necessary while remaining connected to other parts.

Most commonly, ball joints connect upper and lower control arms to your vehicle’s spindles in the front suspension. Your spindle can then move freely when you turn the vehicle’s wheels, allowing you to steer. It also lets your wheel move up or down at certain angles as your suspension compresses and extends to ensure you have as much rubber on the road surface as possible. That could happen when your car hits a bump in the road, or if more weight is applied to a corner of the car under cornering or braking.

HOW TO CHECK A BALL JOINT

When using an aftermarket ball joint like a QA1 Ultimate Ball Joint, you should look at a few things when inspecting it. The first is the amount of play in your ball stud. The stud should be able to move very freely in the cup. However, you should not feel any up-and-down movement between the stud and its housing. If you can feel distinct slop, you should check the ball joint's pre-load.

When looking at the ball joint, make sure the cup is in good shape. If it is welded in, check for cracks in the welds. If it is pressed in, make sure there is no slop between the housing and control arm. Check bolt-in and screw-in ball joints to make sure nothing has backed out or loosened up.

HOW OFTEN SHOULD A BALL JOINT BE INSPECTED OR SERVICED?

This varies depending on the application. If you have a stock or OEM-style ball joint, it’s best to consult a resource like your service manual or contact the manufacturer. Different designs require different service intervals.

When using a low-friction ball joint that is designed to maximize performance, your service intervals will likely shorten. For instance, we recommend inspecting QA1 low-friction ball joints every 2,000-3,000 miles.

If you can no longer add enough pre-load to remove the play from the ball stud, the ball joint likely needs to be replaced.

HOW OFTEN SHOULD A BALL JOINT BE GREASED?

This often depends on the type of ball joint you are using and its application. Stock components may require varying amounts of maintenance and require very different procedures.

If you have QA1 low-friction ball joints, grease them using high-quality lithium grease and check preload on a regular basis. Disassemble them at least annually, every 2,000-2,500 laps or 3,000 miles, whichever comes first. Inspect all parts, clean, and re-adjust preload on the ball stud. Do not OVER grease your ball joints. This can make it difficult for the ball stud to move freely in the cup, or can even cause it to seize.

THERE IS SPACE BETWEEN MY BALL JOINT’S DUST BOOT AND SPINDLE. IS THAT NORMAL?

When using an extended stud – for instance in QA1 Pro Touring Control Arms – it’s common to see space between your dust boot and spindle. The dust boot is designed to help keep road grime and grit out of the ball and socket. It may not reach all the way to the top or bottom of your spindle.

WHAT HAPPENS IF I CHANGE THE LENGTH OF THE BALL STUD IN MY UPPER CONTROL ARM?

You can use the length of your upper ball joint as a tuning device to change the geometry of your front suspension. When you increase the length of your upper ball stud, it generally changes the camber characteristics (both static and dynamic) on the front end of your car. This may help keep the wheel more straight up and down in a straight line. It could also add more negative camber under load to ensure your tire maximizes contact with the road when cornering.

WHAT HAPPENS IF I CHANGE THE LENGTH OF THE BALL STUD IN MY LOWER CONTROL ARM?

Like the upper ball stud length, you can use the length of your lower ball joint to modify your suspension geometry. For instance, you can use it to raise or lower your ride heights. This will also change the instant center and roll center in your vehicle, effectively raising or lowering the center of gravity to increase or decrease body roll during cornering.

I’M USING AN AFTERMARKET SPINDLE AND I CAN’T GET THE CASTLE NUT TO SIT IN THE RIGHT PLACE.

Aftermarket spindles sometimes vary in thickness and material. This can change how much space there is between the spindle and the threads on your stud. You may need to use a washer to take up some of this space. This will let you use a castle nut and cotter pin appropriately. This is not uncommon or anything to worry about, so long as the taper of the ball joint fits the taper of the spindle.

STILL HAVE QUESTIONS? WE CAN HELP.

Our tech team talks ball joints every day. If you’re wondering what ball joint is right for your application or need help with a custom application, feel free to give us a ring or shoot us an email.